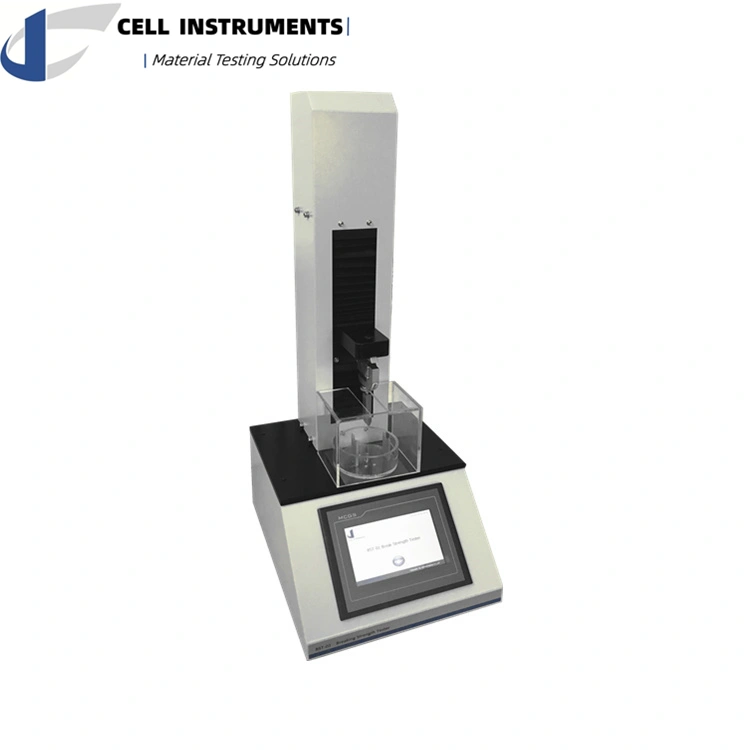

ampoule bottle breaking strength tester

Ampoule Breaking Tester

Glass ampoule breaking testing machine ensures accurate measurement of ampoule strength and safety performance.

About Us

Ampoule Breaking

An Ampoule Breaking Tester is a specialized laboratory instrument designed to measure the breaking force of glass ampoules. It ensures that ampoules comply with international pharmacopoeia standards, such as the European Pharmacopoeia (Ph. Eur.), which specifies requirements for break force, content uniformity, and system suitability testing. This device plays a crucial role in pharmaceutical quality control, safeguarding product safety and user convenience.

Key Features of Ampoule Break Force Testers

- Compliance with Pharmacopoeia Standards – Fully aligned with the European Pharmacopoeia requirements for ampoule break force testing.

- High Accuracy – Digital force sensors provide repeatable and reliable data.

- Versatile Testing – Suitable for different ampoule sizes and shapes.

- System Suitability Testing – Ensures the testing setup is valid before sample evaluation.

- Easy Operation – User-friendly software interface for quick analysis.

Technical Specifications

| Test Force Range | 0 – 200 N (customizable) |

| Resolution | 0.1 N |

| Accuracy | ±0.5% of reading |

| Ampoule Size Range | 1 ml – 30 ml |

| Test Speed | 1 – 500 mm/min adjustable |

| Data Output | USB / RS232 |

| Display | Digital LCD / Touch Screen |

| Power Supply | AC 110 – 220V, 50/60Hz |

| Standards Compliance | European Pharmacopoeia, USP, ISO |

Test Process

- Fixture Selection: Choose a set of metal bars according to ampoule volume.

- Mount ampoule (1, 2, 3, 5, 10, 20, 25, 30mLcapacity).

- Speed Setting: Default 10 mm/min and adjustable

- Breaking: Start the test, and the tester punch descends until neck fracture; high-precision load cell records peak

- Data Handling: The Embedded screen program shows the maximum, minimum, and average break

Why Ampoule Breaking Strength Matters?

Glass ampoules are widely used for storing and delivering injectable medicines.

- Too low breaking force may cause accidental breakage during handling or transport.

- Too high breaking force makes ampoules difficult to open, risking contamination or injury.

Applications in the Pharmaceutical Industry

- Quality Control: Verification of ampoule breaking force during production.

- R&D: Development of new glass packaging materials.

- Regulatory Compliance: Conforming with pharmacopoeia guidelines for drug approval.

- Content Uniformity Testing: Combined with other systems to ensure consistent drug delivery.

Key Standard Requirements

- Breaking force must fall within an acceptable range to avoid safety hazards.

- Glass particle generation must remain within defined limits after breaking.

- System suitability testing must be performed before actual testing to validate accuracy.

- Content uniformity must be maintained to ensure consistent drug dosage.

Reliable Bekk Smoothness Testing for Quality Assurance

Advantages of Our Ampoule Breaking Tester

The ampoule breaking strength tester provides precise measurements, guaranteeing that ampoules meet the optimal balance between safety and practicality.

- High-precision measurement with real-time digital display.

- Wide testing range covering various ampoule types.

- Robust design suitable for long-term industrial use.

- Full compliance with Pharmacopoeia test standards.

- Excellent cost-performance ratio compared to other models.

Conclusion

An Ampoule Breaking Tester is essential for pharmaceutical manufacturers who need to comply with pharmacopoeia requirements and ensure the quality, safety, and usability of glass ampoules. By integrating content uniformity, system suitability testing, and breaking strength analysis, this device guarantees reliable results that support both compliance and efficiency.

Investing in a high-quality breaking force tester not only ensures regulatory approval but also enhances brand reputation by delivering safe and user-friendly medical packaging.

– CELL INSTRUMENTS

Frequently Asked Questions

Q1: Which standards does the Ampoule Breaking Tester comply with?

A1: It fully complies with European Pharmacopoeia (Ph. Eur.), USP <381>/<382>, and relevant ISO standards.

Q2: What is the acceptable breaking force range for ampoules?

A2: According to the European Pharmacopoeia, ampoules must have a breaking force within a defined range, typically 20–65 N depending on ampoule size.

Q3: Why is system suitability testing important?

A3: It ensures that the tester provides accurate and reproducible results before actual ampoule evaluation, maintaining data reliability.

Q4: Can the tester handle different ampoule sizes?

A4: Yes, it supports a wide range of ampoule sizes (1 ml – 30 ml) and can be customized for special requirements.

Q5: How does this tester support regulatory compliance?

A5: By providing precise break force measurements aligned with pharmacopoeia standards, it helps manufacturers meet regulatory approval requirements.

Get in touch

No. 5577 Gongyebei Rd, Licheng, Jinan, 250109, Shandong, P.R.C.

marketing@celtec.cn

+86 185 6001 3985